Manufacturing—Coverings and Upholstering: 1900-1910

The covering is to a frame what attractive wall paper is to a room. The whole effect of a handsome design may be overshadowed by inappropriate covering, just as a wall paper design selected without taste destroys the beauty of fine woodwork and elegant furnishings of a room.—S. Karpen & Bros., 50th Semi-Annual Catalogue (Chicago: S. Karpen & Bros., 1905), aft. 160. Private collection, Emily C. Rose.

Fabric Coverings

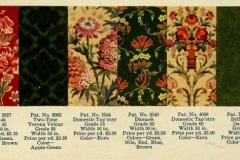

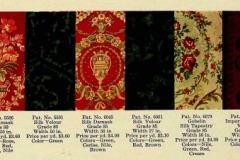

It was with the purchase of upholstery coverings that Solomon Karpen really excelled. He purchased fabrics at the eastern mills and in Europe. The hair cloth used in the Victorian era was replaced with a plethora of new fabrics, the most popular being damask, brocatelle[1] or brocaded Verona or Candago velour in rich colors.[2] In addition many pieces were upholstered in the new fabric, a pure mohair, with the pile woven and prepared so that it gave “a rich and silky appearance.” [3] The mohair was dyed crimson, myrtle, nile green, steel blue, dark blue, olive and cerese colors.[4] Domestic and imported tapestries adorned the more expensive pieces. [5]

In an interview in a furniture trade journal, Solomon explained where he finds new and novel coverings:

Solomon had a special personal connection with the high-end fabric company Stroheim & Romann Company. Julius Stroheim, a Jewish recent immigrant from Silesia, Prussia (at that time), founded J. Stroheim & Son on the Lower East Side of New York in 1882. Julius belonged to many of the same Jewish fraternal organizations as the Karpen brothers.[6] Upon Julius Stroheim’s retirement, his son Salo Stroheim formed a partnership Stroheim & Romann. Salo Romann, who immigrated to America in 1869, was the traveling salesman; in 1910 the company incorporated.[7] Stroheim family members were longtime friends of the Karpen brothers and their descendants.[8]

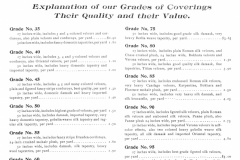

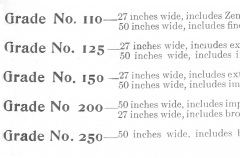

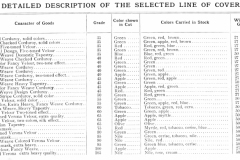

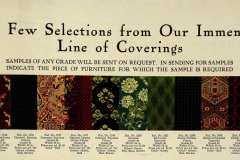

In the Karpen Bros. catalogs that depicted period rooms, detailed information about suitable coverings was included. Several grades of coverings and the corresponding prices were listed under each piece.

In these years, Karpen Bros. added fabric choices to its offerings. In 1902, 14 grades were offered, and in 1909, 19 grades were available. The prices ranged from $.90 per yard to $15.00 per yard depending upon the grade and width of the fabric.

Karpen Bros. provided sample swatches of fabrics to its dealers each season. In a few catalogs it included photographs of small color fabric swatches. Below each swatch, the pattern number, description, grade, width, price per yard, and color choices were listed.

In addition, in certain catalogs an explanation of how to select the correct covering was presented to educate dealers and customers.

Leather Coverings

In its 1897 monthly publication, S. Karpen & Bros. wrote about a leather piece in a manner that set it apart from its competitors: “it is a generally recognized fact that each upholstering shop has a distinctly characteristic way of turning out work, and each piece sent out bears the appearance of belonging to the factory from which it comes. Our leather work has always borne a character and reputation of which we are proud.”[9]

The firm purchased leather in “exceptional quantities” and used labor-saving devices to achieve the greatest value.[10] The massive Chicago slaughter houses provided the necessary supply of cow hides or oxen hides. The process was described in its catalogs:

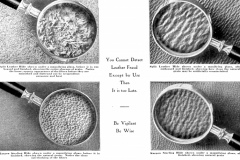

Hides, as they reach the tanner, are about three-fourths of an inch in thickness—too thick to be used in their full substance for upholstery purposes.[11] The tanner therefore using a machine splits the hide into three separate and distinct hides….The valuable hide is the top or natural grain hide. [12] The lower splits, called split leather, have no natural grain and are spongy, fleshy, and quick to decay and show use. [13]

The catalogs also differentiated between genuine leather and split leather. The illustrations covered a hide and contrasting sterling and split leather hide samples under magnifying glasses.

In converting raw hides into leather there is a period of six or eight weeks when the hides are moved along from one tanning vat to another, each solution becoming stronger until the final vat contains nearly pure tannic acid. The tanner’s art is a very old one, and yet it is one in which modern chemistry has made immense advances, both in shortening the time of manipulation and in raining the quality of the leather produced….”[14] It is durable, being oak tanned by slow process; always remains soft, pliable and rich in texture; does not crack or peel like imitations of inferior split leathers. [15]

When the important advertising journal, Printers’ Ink, interviewed Julius Karpen in 1904, he described the Karpen special process:

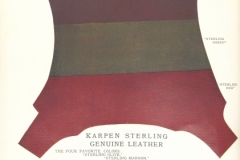

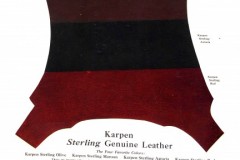

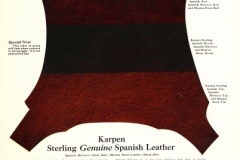

Various types of leather were available in standard or custom colors. The catalogs featured several colored plates that showed the standard colors and then the text described the leather. In its advertisements, it offered “best genuine machine buffed leather in any standard color” [16] or “popular shades.” [17]The colors—olive, maroon, Astoria (black), red—for Karpen Sterling genuine leather were “made on an unvarying formula and of the purest materials.” The tints were “the same, one year with another, and always match the standard shades.”[18]

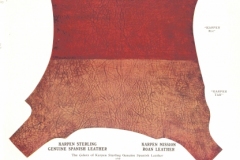

The best quality leather offered was genuine Spanish leather that was available in the same colors. Karpen Bros. described the leather in its Genuine Leather Furniture: “Spanish leather is famous. Spanish leather is known throughout the world for its great beauty of grain and wonderful wearing qualities. Old castles in Spain contain the finest examples existing of mural hangings in decorated Spanish leather. The Sterling brand on Spanish leather assures the genuine.”[19]

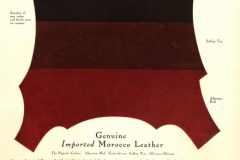

Genuine imported Morocco leather [goat skin] was added to the line in 1905; it was available in the popular colors of Algerian red, Tunis green, Saffran tan, and Sultana blue. Imported Morocco Leather was “the most luxurious, sumptuous covering for furniture known to the modern upholsterer’s art.” [20] The catalog pointed out that much of the Moroccan leather sold in the United States was actually cheap sheepskins that were embossed with the Morocco grain. Those imitations were “clever enough to deceive those who are not experts.”[21]

Introduced by 1904, Mission Roan leather [sheep skin] was available in green red, myrtle, and tan. The company did not recommend or guarantee the Mission Roan leather as the softness of the texture resulted in the colors “wearing away” and “cracking and rough wearing of the surfaces.” [22]

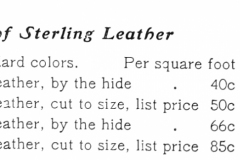

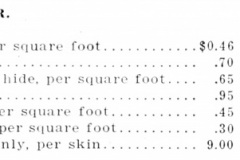

Prices for the various types of hides ranged considerably. Prices for hides and leather cut to size were clearly displayed in the catalogs.

Ever cognizant of potential business opportunities, Karpen Bros. used its huge buying power to engage in an ancillary business of selling fabric and leather to dealers and to small manufacturers and upholsterers.

Upholstering

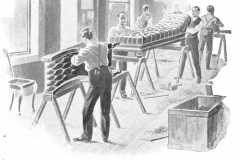

Only a few depictions and photographs of upholsterers have been located. Male craftsmen did hand-work in conjunction with mechanization with the Automatic Tufting Machine. Automatic Tufting Machine. The upholstering technique was touted as “the tufts were all deep and evenly drawn.”[23]

In 1900 “in Karpen Bros.’ factory six car loads of tacks are used in one year” in securing the upholstery to the frame.[24] The gimp so popular in the Victorian era was replaced in some designs by a cleaner process: the cover was “folded in around the entire edge and tacked down with large size brass nails placed very close together.” This produced “a clean edge and takes away the possibility of a ragged and dust catching gimp.”[25]

The furniture trade journals visited the Karpen factory and noted that “every step in the selection of materials, in the assembling of the parts, down to the finishing and packing” was “watched with a care which permits only a perfect and salable product to reach the dealer’s floor.”[26] In an advertisement Karpen Bros. assured its potential customers that “20 Inspections to Safeguard you. …. None but the most precautionary manufacturing methods can be used. So extremely careful are we that at each step in the process the work is rigidly inspected. Twenty inspections are necessary on a single Karpen piece.” [27]

A story about Solomon illustrated his meticulous care to detail in the factory. Solomon was on the floor of the factory making his rounds. In the Upholstery Department, he saw a small pile of tacks on the floor. He knew that an upholsterer would put tacks in his mouth and then bring them out one by one to then hammer in. Solomon strongly reprimanded the worker for being profligate: he was being wasteful by putting too many tacks in his mouth for the job!

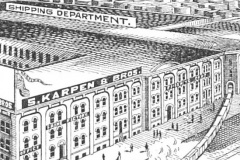

Shipping

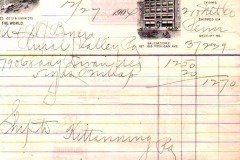

Each piece was wrapped in burlap for shipment and was loaded on railroad cars in the factory’s railroad shed. Using consolidated cars, the shipping rates per 100 pounds to large railroad distribution points ranged from $0.30 to Midwest cities, $1.16 to the south and $2.20 to the west coast. [28] From these central shipping destinations, dealers in smaller cities and towns could then pay an additional “small charge for handling and transferring, plus the local rate to their home city.”[29]

Note: In these years, some materials in S. Karpen & Bros.’ catalogs were similar. Content and presentation varied slightly as did the location of the pages in the catalog. All catalogs written and published by S. Karpen & Bros. Catalog dimensions: ca. 11 inches by 15 inches. All private collection, Emily C. Rose. Catalogs referenced–Fabrics (F), Leather (L):

44th Semi Annual Catalogue. 1902, (F) aft. 68. 47th Semi Annual Catalogue. 1903, (F) 95.49th Semi Annual Catalogue. 1904, (F) aft 134; (L) aft. 48. 50th Semi-Annual Catalogue. 1905, (F) aft. 160; (L) aft. 80. 26th Annual Catalogue. 1906, (F) 4; (L) aft. 112. 27th Annual Catalogue. 1907, (F) bef. 6; (L) aft 104. 28th Annual Catalogue. 1908, (F) 7; (L) 71-4, 75. 29th Annual Catalogue. 1909, (F) 8; ((L) 32-5.

- S. Karpen & Bros., Upholstered Furniture (Chicago: S. Karpen & Bros., 1897), p. Style 2573. Munsey’s Magazine, June and Sept. 1907, n.p. ↑

- S. Karpen & Bros., Upholstered Furniture (Chicago: S. Karpen & Bros., 1897), p. Style 2437. Munsey’s Magazine, Nov. 1901, n.p. McClure’s Magazine, 1901. McClure’s Magazine, Feb. 1902, 31. McClure’s Magazine, Mar. 1902, 90. ↑

- Furniture Worker, Apr. 10, 1901, 35. Munsey’s Magazine, June and Sept. 1907, n.p. ↑

- Furniture Worker, Apr. 10, 1901, 35. ↑

- Furniture Worker, Apr. 10, 1901, 35. Munsey’s Magazine, Aug. 1908, n.p. ↑

- “Obituary, Julius Stroheim,” Furniture Trade Review, Nov. 10, 1899, 19. ↑

- “Obituary Salo Romann.” Upholsterer, Oct. 18, 1912, 82. ↑

- Solomon Karpen’s granddaughter, Ruth Berliss Ciner. (Interview with Emily C. Rose, 1993.) Wedding gifts list, Marie Karpen Berliss, 1910. Private collection, Emily C. Rose. ↑

- S. Karpen & Bros., Upholstered Furniture (Chicago: S. Karpen & Bros., June, 1897), p. Style 2630 ½. ↑

- S. Karpen & Bros., 29th Annual Catalogue (Chicago: S. Karpen & Bros., 1909), 31. ↑

- S. Karpen & Bros., 27th Annual Catalogue (Chicago: S. Karpen & Bros., 1907), aft 104. ↑

- S. Karpen & Bros., 27th Annual Catalogue (Chicago: S. Karpen & Bros., 1907), aft 104. ↑

- S. Karpen & Bros., 27th Annual Catalogue (Chicago: S. Karpen & Bros., 1907), aft 104. S. Karpen & Bros., 29th Annual Catalogue (Chicago: S. Karpen & Bros., 1909), 31. ↑

- S. Karpen & Bros., 29th Annual Catalogue (Chicago: S. Karpen & Bros., 1909), 31. ↑

- McClure’s Magazine, Sept. 1902, 114. Ladies Home Journal, Oct. 1902, 42. ↑

- McClure’s Magazine, June 1901, 62. ↑

- Munsey’s Magazine, Dec. 1901, n.p. ↑

- S. Karpen & Bros., 29th Annual Catalogue (Chicago: S. Karpen & Bros., 1909), 34. ↑

- S. Karpen & Bros., Genuine Leather Furniture (Chicago: S. Karpen & Bros., 1902), 27. ↑

- S. Karpen & Bros., 27th Annual Catalogue (Chicago: S. Karpen & Bros., 1907), aft. 104. ↑

- S. Karpen & Bros., 27th Annual Catalogue (Chicago: S. Karpen & Bros., 1907), aft. 104. ↑

- S. Karpen & Bros., 27th Annual Catalogue (Chicago: S. Karpen & Bros., 1907), aft. 104. ↑

- S. Karpen & Bros., Upholstered Furniture, 1897 (Chicago: S. Karpen & Bros., June, 1897), p. Style 2630 ½. ↑

- Furniture Worker, Mar. 25, 1900, 34. ↑

- S. Karpen & Bros., Upholstered Furniture (Chicago: S. Karpen & Bros., 1897), p. Style 2437. ↑

- Furniture World, Jul. 28, 1904, 46. Furniture Journal, Nov. 10, 1909, inside cover. ↑

- Saturday Evening Post, Nov. 12, 1910, 42. ↑

- S. Karpen & Bros., 50th Semi-Annual Catalogue, 1905, (Chicago: S. Karpen & Bros., 1905), title page. ↑

- S. Karpen & Bros., 50th Semi-Annual Catalogue, 1905, (Chicago: S. Karpen & Bros., 1905), title page. ↑